Total Productive Maintenance

In Field Training

Arad, 4-6 October

Significant increase in operational availability by eliminating and preventing losses

Why Total Productive Maintenance?

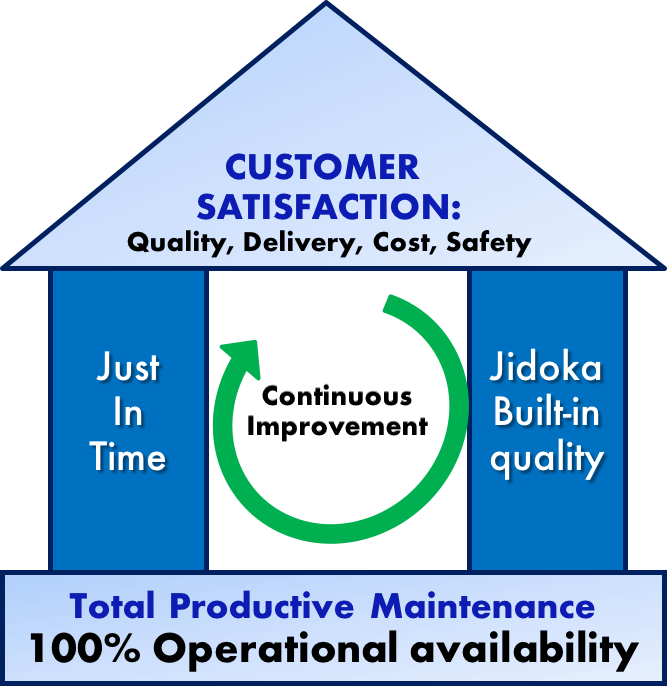

50 years ago Toyota recognized that the key to manufacturing success is when the machinery performs as expected from the design specifications.

The base of a successful production system is “Total Productive Maintenance (TPM)”

Many manufacturers soon realize in their pursuit of Lean that poor productivity is their main barrier to manufacturing excellence.

This training will give participants the foundation necessary to start the first steps of the TPM implementation.

Host Company: BOA Below Technologies Romania

The BOA Group is one of the world’s leading manufacturers for flexible mechanical elements for the automotive and aerospace industry as well as for a wide range of industrial applications.

The headquarters is based in Stutensee, Germany. Today, the BOA Group consists of 15 subsidiaries and shareholdings in 13 countries.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

BOA Romania is located in Arad. The plant started its operations in July 2014 producing metal hoses and exhaust gas recirculation pipes for the automotive industry as well as V-clamps for industrial applications.

The BOA Group develops, produces and distributes flexible stainless steel components for engine management, exhaust systems, fuel systems and side components for passenger cars and heavy vehicles.

In the industrial division, the BOA Group delivers flexible elements for applications in the Energy sector, Shipbuilding, Rail and Heavy Engine industry. Customized expansion joints are designed for Petrochemical, Chemical as well as Oil & Gas Pipelines.

Precision metal bellows and ultra clean metal hoses complete the product range and offer high tech product applications in the Vacuum, Semiconductor & Magnet Technology market.

Zona Industriala Nord-Vest, str. IV, Nr. 13, Arad, Romania.

Understand the TPM System

Identify and analyze the operational losses using TPM management tools and structure.

Team up with other managers

Share experiences and discuss with other colleagues from different industries

Genba Activities

We will apply different TPM concepts directly on the host plant process

Training Lenght:

24 Hours (3 days)

Available seats

25 participants

Recommended Industries

Manufacturing Companies: Automotive, Electrical/Electronic, Pharmaceutical, Food & Beverages, Printing, Plastics, among others.

Who should attend?

General Managers, Managers and Supervisors in Maintenance, Lean Managers that would like to understand the implementation of TPM

- The Concept of TPM – Total Productive Maintenance link to Operational Excellence

- Understanding and Improving Overall Equipment Effectiveness –

- Elements of TPM Management

- Early Equipment Management –

- Good equipment definition

- Preparation for Manufacturing/Maintenance

- Target setting

- TPM performance Indicators – (OEE, MTTR, MTBF, Maintenance Cost.)

- Equipment Prioritization

- Preventing Failure Occurrence:

- – Autonomous Maintenance

- – Periodical & Predictive Maintenance

- Failure repair quick and accurate

- Kaizen – Failure analysis & recurrence prevention

- Establish a PDCA mindset for TPM activities

- Human Resources Development – training for operations & maintenance team

- Maintenance Cost Management

- TPM Work Management (Visual & Standard work)

Instructor